Confined Space Inspection

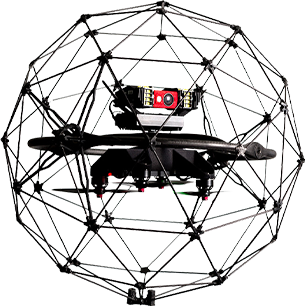

The visual inspection of tanks was used to performed by workers suspended on ropes to inspect the tank structure which are required on a regular basis, focus on areas of high stress such as stiffeners, brackets, bracing and stringers and assess the coating condition and check for corrosion and damage within the tank. However, that access methods including staging, rafting, and climbing are often used by surveyors to access tanks to carry out their observations. Traditional methods to tank surveys therefore have three main drawbacks: high set-up costs; longer inspection times and a high risk of workman injury on site. For the surveyor, the task typically involves high rope access, working within a confined space, often for extended periods of three to four days. Now with drone surveys require no human access to the tank and since no access equipment is required, there are no setup costs and inspections can be completed within one day.

Benefit of using a drone over traditional staging inside the tank, drones allows to capture every corner and inch of the most complex and confined assets, from a safe location. Inspections using drones are offered to ballast tanks, containerships, cargo tanks of floating production storage and off-loading vessel, or remote structural components in cargos and ships tanks.

The inspections of elements such as:

- Storage Silos

- Tankers, Clean Tankers, Chemical Tankers, Crude Oil Tankers, Dirty & other tankers

- Sewers inspection

- Pipeline Inspection

- Access Shafts inspection

- Boilers inspection

- Manholes inspection

- Ballast tanks inspection